Table of Contents

Introduction

The semiconductor industry is the backbone of modern technology, powering everything from smartphones and medical devices to AI systems and electric vehicles. But chipmaking is also one of the most resource-intensive industrial activities in the world, demanding ultra-pure water, uninterrupted power, and hazardous chemicals. This makes sustainability a pressing concern in the global semiconductor supply chain.

India, with its growing semiconductor ambitions, is taking a distinctive path—embedding ecological safeguards into its semiconductor roadmap from the very beginning. Unlike traditional hubs that struggle to retrofit sustainability measures, India is leveraging its “greenfield advantage” to align semiconductor expansion with climate goals, ecological resilience, and global competitiveness.

The Environmental Cost of Chips

Chip production is energy- and resource-intensive at every stage:

- Water Use: A single fabrication facility (fab) can consume millions of liters of ultra-pure water daily. In water-scarce regions like Taiwan, this has created conflicts between farmers and fabs.

- Energy Demand: Advanced tools like EUV machines consume vast amounts of electricity, mostly generated from fossil fuels, intensifying carbon footprints.

- Chemical Risks: The use of toxic gases and chemicals like perfluorocarbons (PFCs) creates long-lasting environmental hazards.

- Material Extraction: Mining silicon, tungsten, gallium, and cobalt leads to deforestation, water contamination, and biodiversity loss.

These challenges underline why a sustainable model for semiconductor manufacturing is crucial.

India’s Sustainable Semiconductor Strategy

India’s approach rests on three interconnected priorities:

- Green Fabs: Incentives for semiconductor fabs that recycle water, minimize emissions, and meet global environmental standards. This prevents ecological damage while strengthening resilience.

- Circular Supply Chains: Moving from the “make–use–dispose” model to a reuse-and-recycle framework for semiconductor materials, chemicals, and components. This reduces environmental impact and geopolitical vulnerabilities.

- Renewable-Powered Facilities: Encouraging fabs to rely on renewable energy and sustainable utilities, ensuring that growth doesn’t come at the expense of ecological balance.

Building a Green Ecosystem: The 13 MoUs

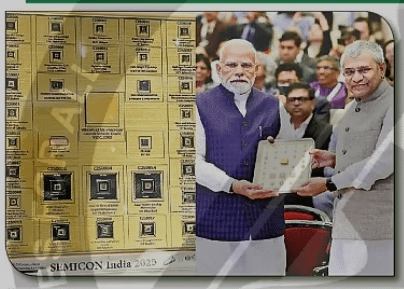

At Semicon India 2025, 13 Memorandums of Understanding (MoUs) were signed to boost innovation, advanced manufacturing, and sustainable practices. These cover:

- Advanced Packaging: Using recyclable and reusable materials to cut waste.

- Talent Development: Training engineers and technicians in green manufacturing practices.

- Collaborative R&D: Joint projects focusing on eco-friendly semiconductor materials and energy-efficient design.

Workforce and Skills: Greening the Talent Pipeline

India plans to train one million semiconductor professionals by 2030, not only in chip design and manufacturing but also in environmental sustainability. Universities, research institutions, and industry collaborations are aligning curricula to include renewable energy, water management, and green packaging solutions.

India’s Unique Position: A Greenfield Advantage

Unlike older semiconductor hubs that must retrofit sustainability into decades-old infrastructures, India is starting afresh. This greenfield advantage allows new fabs to adopt renewable energy, advanced recycling, and low-emission technologies from day one.

This positions India not only as a competitive semiconductor hub but also as a trusted global partner for ESG (Environmental, Social, and Governance)-driven corporations seeking sustainable supply chains.

Government Push and Career Opportunities

The Ministry of Electronics and IT (MeitY) has launched multiple schemes to boost the electronics and semiconductor sector:

- Skill Development Schemes to train youth in semiconductor design and manufacturing.

- Support for ESDM Startups through R&D funding, incubation programs, and global partnerships.

- Careers in Government & PSUs like BEL, BHEL, C-DOT, and ECL, which need skilled semiconductor professionals for defense, telecom, and energy sectors.

Private sector opportunities are also surging, especially in chip design, AI-driven electronics, robotics, and advanced packaging, making India’s semiconductor workforce one of the most sought-after globally.

A Future That Looks Brighter Than Ever

India’s goal of achieving a $300 billion electronics manufacturing sector by 2026 is ambitious but achievable. With global giants, domestic startups, and government initiatives aligning, the country is setting the stage for an ecosystem that blends innovation, sustainability, and scale.

The journey won’t be without challenges—water scarcity, energy needs, and supply chain resilience remain hurdles. But India’s proactive sustainability-first approach ensures that its semiconductor growth does not repeat the ecological mistakes of past industrial revolutions.

Conclusion

India is crafting a climate-conscious semiconductor blueprint that could redefine how chips are made and consumed globally. By integrating sustainability from day one, the country is not just building fabs but shaping the future of technology with responsibility.

As the world seeks green supply chains, India’s green chips promise not only global impact but also a sustainable edge in the semiconductor race.